Skin Care Product Equipment

BIOCROWN Fully Equipped Skin Care Production Line

As a GMP skincare product manufacturer, BIOCROWN has complete production and packaging lines. We've been upgrading our production technologies and equipment to support our clients' demands and meet their expectations.

We have emulsifier mixers weighing 50kg to 250kg, and agitating and heated mixing tanks weighing 100kg to 2,000kg. Other process equipment, including RO water system, computerized quantitative filling machine, professional mask filling sealers, auto liquid filling capper machine system, tube filling & sealing machinery, ampoules capper machine, bar soap stretch wrapper, overwrapping machine, horizontal auto-wrapping machine, shrink packaging machine, Linx 7300 printing machine, conveyor belt packaging machine, orbital bottle washing machine, high-temperature sterilization tunnel oven and automatic soap machine etc. All are equipped at our GMP production plant to create safe, trusted quality products for our clients.

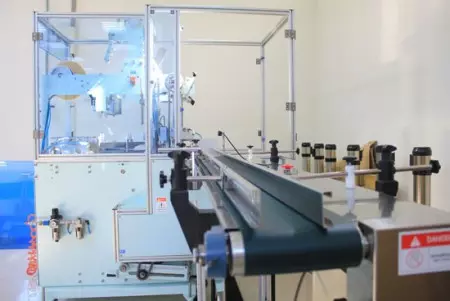

Skin Care Product Filling and Sealing Machine - High Production & Easy to Clean

The filling and sealing machine is suitable for soft-tube end-sealing of all skin care products. It is hygienic, efficient and productive compared to the conventional one, allows us to speed up the filling process without bubbles to keep high productivity. Also, the manufacturing date can be printed during the tube formation, which prevents modification.

With the new filling and sealing machine, plastic tube cleaning is done by air blowing and static can be avoided during the filling process. The filling section of the machine is made of stainless material SUS316 to prevent contamination. To seal up, there are multiple shapes for your selection, such as R, curve, hanging and wavy. With PLC automatic control system and touch-screen of the machine, every station of the operating process is precisely controlled.

Facial Mask Process Equipment & One-Stop Production Line

Our automatic sheet mask production line is designed to have high production capacity and to manufacture various facial masks with precise operation. Whether it's for functional sheet masks such as moisturizing, soothing, anti-aging, firming, repairing, whitening, or bio-cellulose sheet masks for intensive care etc., BIOCROWN supplies high-quality one-stop production.

From the insertion of the mask sheet, filling, pressing, sealing, batch code/mfg and expiry dates printing to leaking test, all the steps can be done at the same line to save time and cost.

Facial Mask Manufacturing Steps:

1. Inserting sheet mask into a sachet

2. Placing sachet on the conveyor

3. Filling serum into sachet.

4. Press the filled mask to ensure the mask is soaked with nutritious ingredients.

5. Sealing

6. Mfg/expiry date printing

7. Leaking test

- Equipments

- 50KG Automatic Vacuum Emulsifying Mixer

- 100KG Automatic Three Vacuum Emulsifying Mixer

- Vacuum Agitating Emulsifying Mixer

- 100KG Vacuum Agitating Tank

- Movable High Speed Mixer

- Heated Mixing Tank

- Heated Mixing Tank

- Professional Mask Filling Sealers

- Professional Mask Filling Sealers

- Auto Liquid Filling Capper Machine

- Tube Filling & Sealing Machine

- Ampoules Capper Machine

- Bar Soap Stretch Wrapper

- Bar Soap Stretch Wrapper

- Bar Soap Stretch Wrapper

- Bar Soap Stretch Wrapper

- Automatic Soap Machine

- Overwrapping Machine

- Filling Machine

- Linx 7300 Printing Machine

- Autoclave

- Conveyor Belt Packing Machine

- Orbital Bottle Washing Machine

- Shink Film Packing Machine