3 Hidden Risks of Choosing Low-Cost OEM Factories

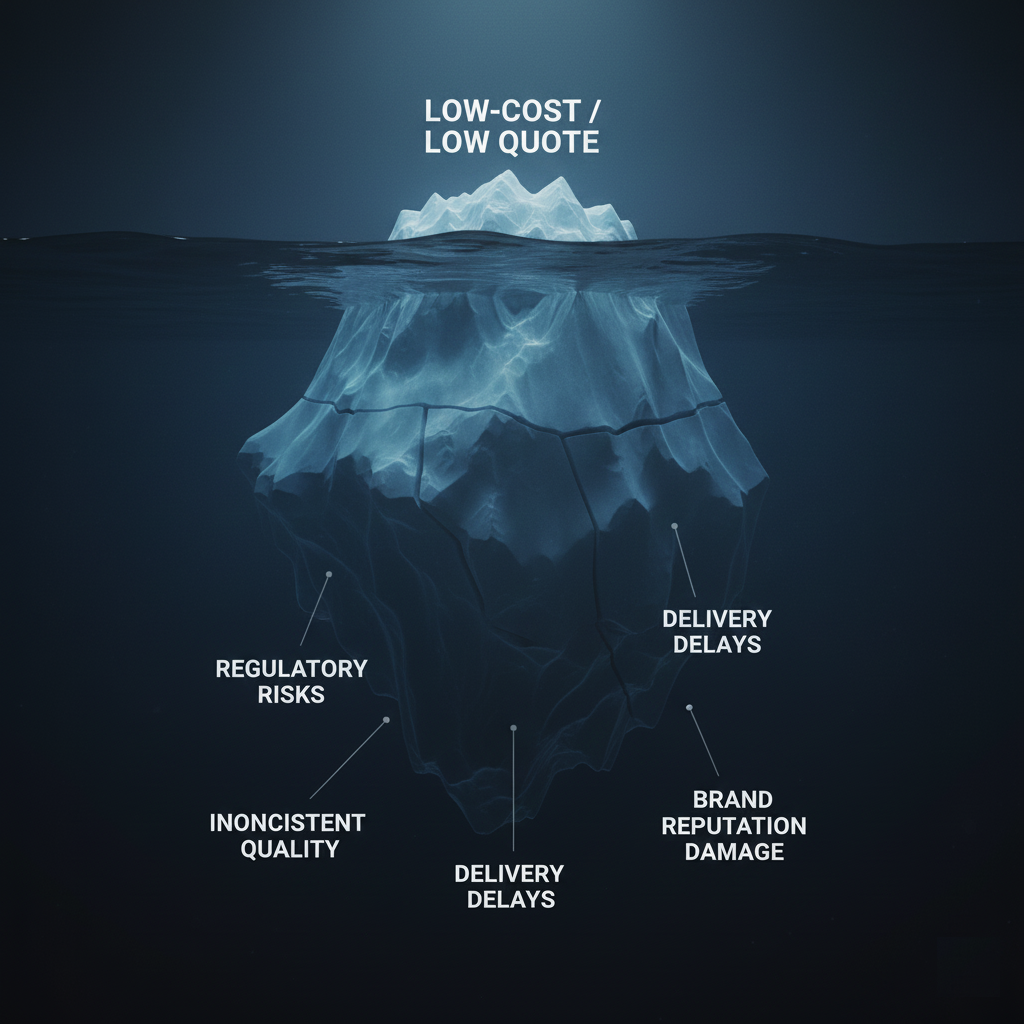

In today’s highly competitive beauty and skincare market, cost pressure is real. Many brands (especially during early growth or expansion) are tempted to choose low-price OEM manufacturers to protect margins.

However, what appears “cost-effective” on paper often exposes brands to far greater financial, regulatory, and reputational risks down the line.

As a GMP-certified OEM partner specializing in biochemical R&D since 1977, BIOCROWN has seen firsthand how brands fail—not because of marketing, but because of manufacturing shortcuts. Below are the three hidden risks most commonly associated with low-cost OEM factories, and how a certified cleanroom infrastructure fundamentally changes the outcome.

Why “Cheaper” Often Becomes the Most Expensive Decision for Beauty Brands

× Risk 1: Invisible Threats— Microbial Contamination & Cross-Contamination

Low-price OEM factories often reduce costs by compromising production environment controls.

The Hidden Problem

Manufacturing in non-cleanroom or semi-open environments allows airborne particles, microorganisms, and residue from previous batches to contaminate products. This significantly increases the risk of exceeding microbial limits (e.g., Pseudomonas aeruginosa, mold, yeast).

Once products reach the market, brands may face

Product spoilage, Unpleasant odors or texture changes, Skin irritation or inflammation in end users.

The True Cost

Global product recalls, Legal liability and compensation claims, Permanent damage to brand trust and credibility.

× Risk 2: Formula Instability — The After-Sales Nightmare

High-performance formulations require precise environmental control during production.

The Hidden Problem

Low-cost OEM facilities often lack temperature- and humidity-controlled environments. Many active ingredients (Vitamin C, peptides, or advanced waterless systems) are highly sensitive to environmental fluctuation.

Without controlled conditions, products may experience

Phase separation, Color changes, Oxidation and loss of efficacy within months on shelf.

The True Cost

High return rates, Distributor and retailer complaints, Loss of channel confidence—often fatal for emerging brands.

× Risk 3: EU PIF & International Regulatory Failure

For brands targeting the EU, UK, or global markets, regulatory compliance is non-negotiable.

The Hidden Problem

Low-price OEM manufacturers frequently cannot provide: Complete batch records, Environmental monitoring data, Toxicological safety documentation.

When auditors request microbial control data or production traceability, missing documentation leads to EU PIF rejection and immediate sales bans.

The True Cost

Missed international expansion opportunities, Sunk costs in marketing, Delayed or canceled global launches.

BIOCROWN’s Answer: Why a Class 10,000 Cleanroom Is a Strategic Asset

To eliminate these risks at their root, BIOCROWN has invested heavily in Class 10,000 cleanroom manufacturing environments. This is not merely a “cleaner factory”—it is a risk management system designed for global OEM brands.

✔ Advanced Microbial Control

HEPA filtration systems and controlled air pressure gradients strictly limit airborne particles (>0.5 μm), reducing contamination risk to near-zero levels.

✔ Temperature & Humidity Stability

Designed for high-stability formulations, our cleanrooms ensure active ingredients remain protected from raw material loading through final packaging—supporting long-term shelf stability.

✔ Single-Strain Fermentation Advantage

Combined with BIOCROWN’s proprietary Single-Bacteria (Acetobacter) fermentation technology, each biocellulose mask or hydrogel product is cultivated independently in controlled conditions—meeting medical-grade purity standards.

Cheap Manufacturing Is Often the Most Expensive Choice

When an OEM quotation appears unusually low, the hidden cost is almost always environmental control. For brand owners, the savings of a few cents per unit can quickly turn into: Regulatory shutdowns, Public relations crises, Irreversible brand damage

BIOCROWN’s pricing reflects absolute accountability for quality, compliance, and long-term brand safety. Choosing ISO-certified cleanroom manufacturing is not a cost—it is an investment in your brand’s future.