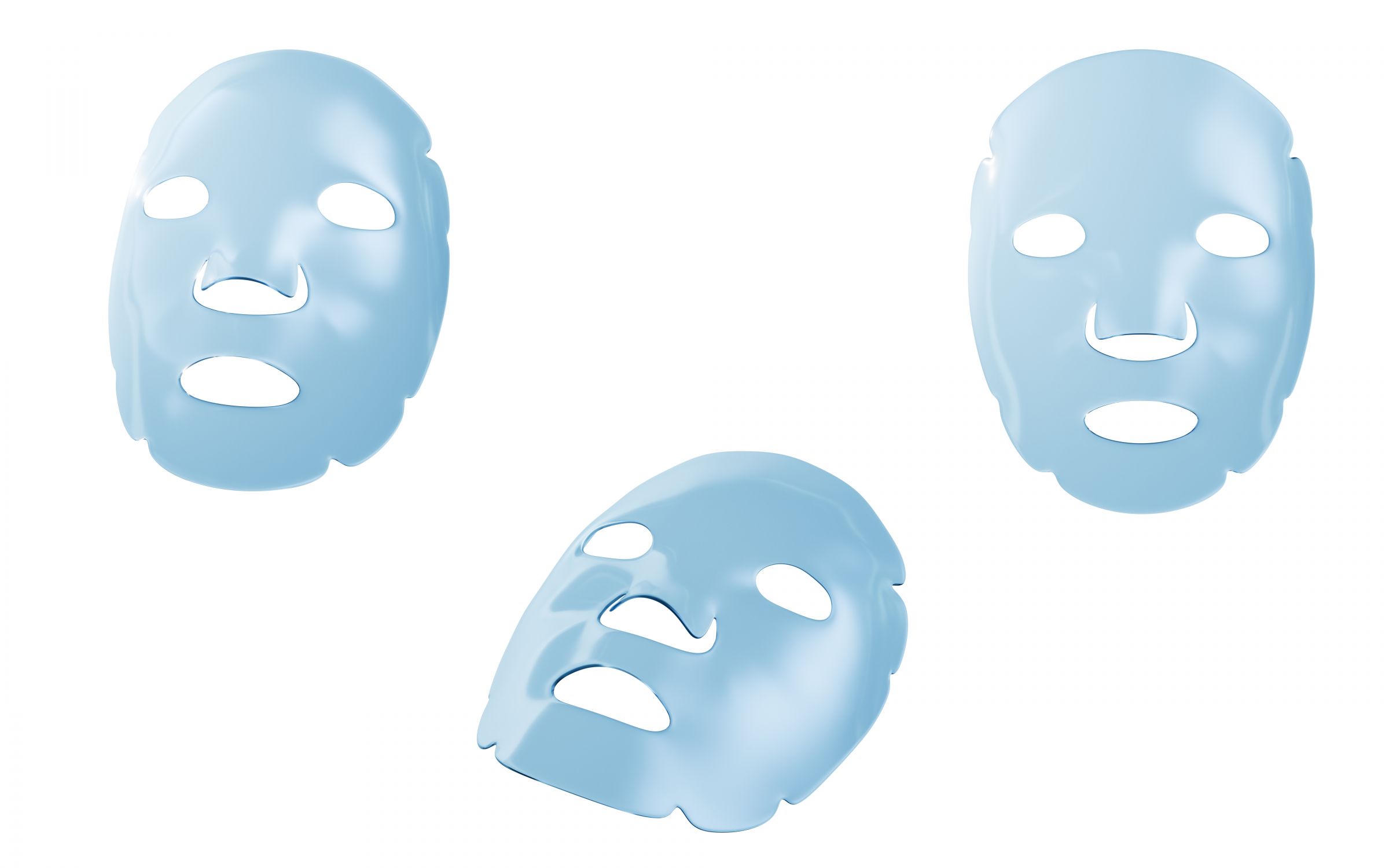

100% Natural Bio-Cellulose Masks: The Key to Next-Level Skincare Innovation

"Bio-cellulose masks: Genuinely natural, not a 'greenwash'."

As natural, sustainable, and environmentally conscious beauty becomes a critical brand proposition, the focus on truly natural mask materials is intensifying. Bio-cellulose masks stand out not just for their superior efficacy, but also because the mask material itself is an entirely natural, 100% plastic-free, and environmentally sound option.

Skincare Technology Born from Nature

As natural, sustainable, and environmentally conscious beauty becomes a critical brand proposition, the focus on truly natural mask materials is intensifying. Bio-cellulose masks stand out not just for their superior efficacy, but also because the mask material itself is an entirely natural, 100% plastic-free, and environmentally sound option.

The structure of bio-cellulose masks comes from cellulose, synthesized by natural microorganisms (like Acetobacter xylinum) through fermentation. Its chemical structure is identical to the cellulose found in plants.

˙Natural Origin: It's not a petrochemical plastic product (like PP or PET). Instead, it's a natural polymer synthesized by microorganisms "eating" natural sugar sources such as glucose or coconut water.

˙Biodegradable: After use, this fiber can be completely decomposed by microorganisms in nature, making it a truly eco-friendly material that can "return to nature."

˙Plastic-Free Fiber: Unlike non-woven or synthetic fiber masks, whose material itself contains plastic molecules that may shed and leave residue during use.

1. Physical Exfoliation

This method uses scrubbing particles (e.g., microbeads, crushed seeds, or brush heads) to manually remove dead skin cells. The result is immediate smoothness and clarity, making it popular for quick results. However, for sensitive or dry skin, improper technique or excessive frequency can lead to irritation and micro-damage.

✅ Ideal for: Normal to oily skin, quick-result treatments

⚠️ Caution: Not recommended for daily use on sensitive or compromised skin

2. Chemical Exfoliation

Utilizing active ingredients such as AHAs (e.g., glycolic acid), BHAs (e.g., salicylic acid), or enzymes, this method works at a cellular level to dissolve the bonds between dead skin cells, allowing them to shed naturally. Chemical exfoliation is generally gentler and more uniform, though it requires consistent use for visible results.

✅ Ideal for: Sensitive skin, uneven texture, or anti-aging routines

🔄 Effect: Gradual but long-lasting improvements in skin texture and tone

As a professional OEM/ODM skincare manufacturer, Biocrown offers a wide range of exfoliating products tailored to diverse market needs—from instant-result scrubs to gentle, leave-on exfoliants suitable for daily use.

We provide:

• Custom formulations: AHAs, BHAs, PHA, enzymes, jojoba beads, volcanic ash, etc.

• Skin-type-specific solutions: From sensitive skin to acne-prone or mature skin

• Eco-friendly and natural options

• Flexible packaging: Tubes, jars, sachets, pump bottles

📩 Contact us today to develop your own exfoliator product line — customized for your market, your customers, and your brand vision.

.png?v=b9028d36)