Skin Care Product Production Lines

Organic and Natural Skin Care Product Manufacturer – BIOCROWN

As one of the leading GMP-certified manufacturers of skincare products, BIOCROWN provides comprehensive one-stop services for private label and white label manufacturing. We maintain rigorous quality standards, evidenced by our certifications including ISO 22716:2007, ISO 9001:2008, ISO 14001:2015, and Ecocert, among others.

Tracing our roots back 48 years, BIOCROWN began by specializing in bar soaps, essence oils, hand creams, and baby lotions. Over this time, we have built immense value through developing numerous bespoke formulas and gaining extensive, seasoned processing experience based on evolving client needs. Whether a skincare product requires the incorporation of unique ingredients like essence oils, chlorophyll, charcoal, or herbs, or simply needs ingredient modification to enhance moisture or scent, every requirement is meticulously assessed before proceeding with development.

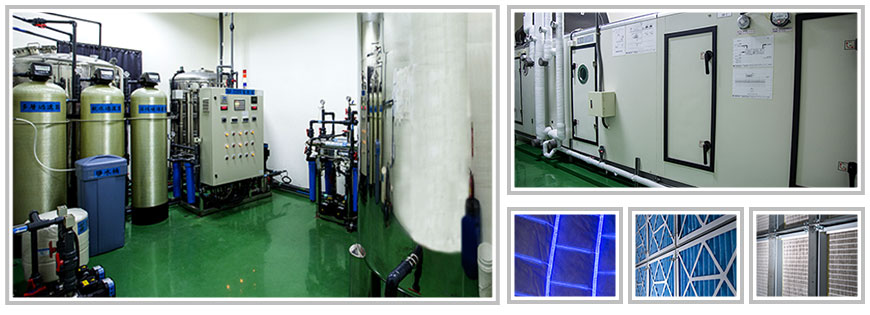

BioCrown has set up RO Reverse Osmosis pure water equipment and first class Microcomputer Air Conditioning Control System

Manufacturing Process of Skin Toner

- (A) Ingredient: WATER, HYALURONIC ACID, GLYCOSYL TREHALOSE, HYDROGENATED STARCH HYDROLYSATE, PANTHENOL, NIACINAMIDE, ASCORBYL GLUCOSIDE, PUNICA GRANATUM EXTRACT.

- (B) Ingredient: GLYCERIN, PHENOXYETHANOL, CHLORPHENESIN.

Manufacturing Process of Bar Soap

- (A) Ingredient: WATER, ETHANOL, SODIUM COCOATE, PROPYLENE GLYCOL, SODIUM MYRISTATE, SODIUM STEARATE, SORBITOL, SODIUM LAURATE, SODIUM PALMITATE, SUCROSE, SODIUM CHLORIDE.

- (B) Ingredient: FRAGRANCE.

Manufacturing Process of Essence Oil

- (A) Ingredient: CAMELLIA OLEIFERA SEED OIL, SIMMONDSIA CHINENSIS (JOJOBA) SEED OIL, BABASSU OIL, ARGANIA SPINOSA KERNEL OIL, ROSA RUBIGINOSA SEED OIL.

- (B) Ingredient: TOCOPHERYL ACETATE, CAPRYLIC/CAPRIC TRIGLYCERIDE.

Manufacturing Process of Cream

- (A) Ingredient: WATER, GLYCOSYL TREHALOSE, HYDROGENATED STARCH HYDROLYSATE, GLYCERIN, PROPANEDIOL, CHLORPHENESIN.

- (B) Ingredient: CETEARYL OLIVATE, SORBITAN OLIVATE, MYRISTYL MYRISTATE, CAPRYLIC/CAPRIC TRIGLYCERIDE, SQUALANE.

- (C) Ingredient: PANTHENOL, NIACINAMIDE, MORINGA PTERYGOSPERMA SEED EXTRACT, CAMELLIA SINENSIS LEAF EXTRACT, BIOSACCHARIDE GUM-1, PHENOXYETHANOL, SERENOA SERRULATA FRUIT EXTRACT, HYALURONIC ACID, SIMMONDSIA CHINENSIS (JOJOBA) SEED OIL, ARGANIA SPINOSA KERNEL OIL.

Manufacturing Process of Moisturizer

- (A) Ingredient: CAPRYLIC/CAPRIC TRIGLYCERIDE, BEE WAX, BUTYROSPERMUM PARKII (SHEA BUTTER), PETROLATUM, THEOBROMA CACAO (COCOA) SEED BUTTER, LANOLIN.

- (B) Ingredient: TOCOPHERYL ACETATE.

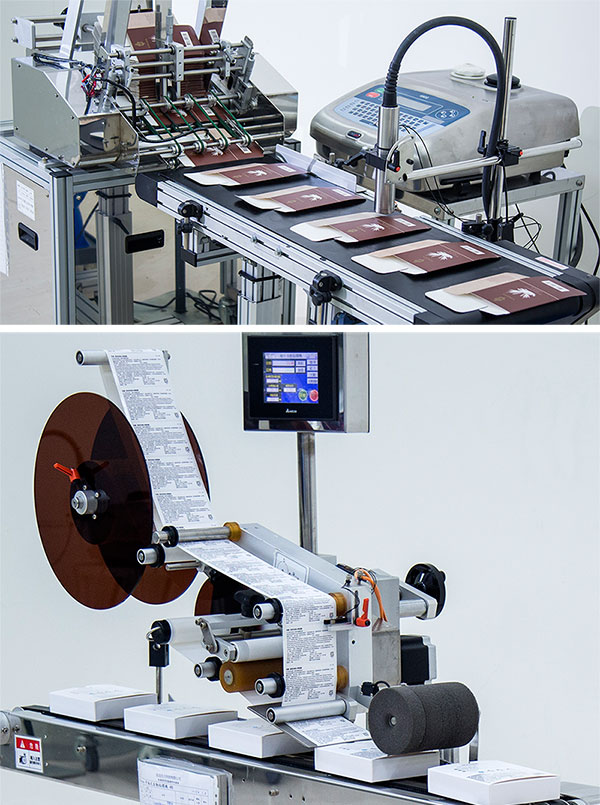

- Equipments

- Orbital Bottle Washing Machine

- Bottle Drying Machine

- Automatic labeling machine

- Auto Liquid Filling Capper Machine System

- Tube Filling & Sealing Machine

- Automatic Sheet Mask Filling and Sealing Machine

- Auto Liquid Filling Capper Machine

- Hand Cream Packaging

- Sheet Mask Packaging

- POF Shrink Film Machine

- POF Shrink Film Machine

- Automatic labeling machine

- Cellophane Wrapping Machine

- Printing Machine