Integrating "Facial Gua Sha" as a High-Performance Delivery System for Your Skin Care Line

In the premium spa and clinical skincare market, product efficacy is only part of the equation. Increasingly, treatment outcomes are shaped by how products are delivered to the skin.

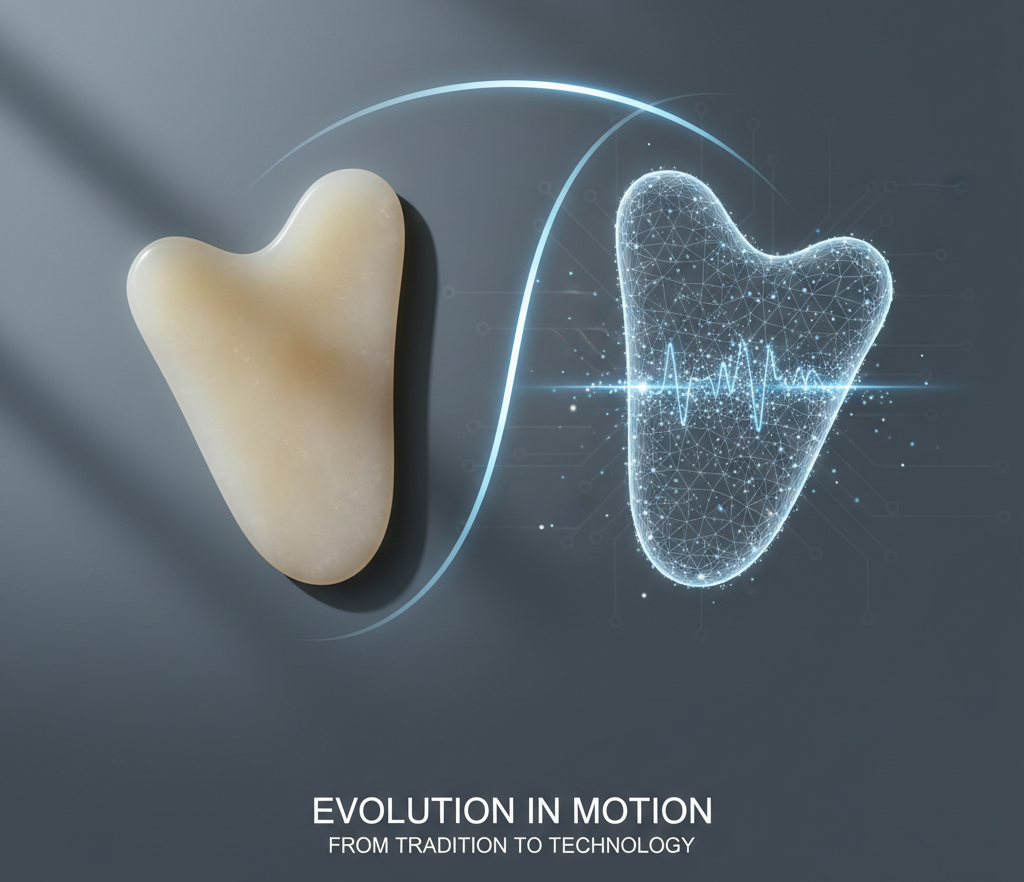

From Ritual to Results: The Science of Modern Gua Sha Delivery Protocols

Modern Gua Sha has evolved beyond a traditional ritual into a mechanical lymphatic drainage (MLD)–inspired skin activation protocol. Through controlled, non-invasive mechanical stimulation, this technique helps activate microcirculation and temporarily enhance skin receptivity, creating optimal conditions for skincare application. Research in skin physiology suggests that mechanical stimulation may support improved skin permeability and more efficient interaction between active ingredients and the skin surface during a defined post-treatment window. When paired with well-formulated serums or concentrates, this delivery protocol can help maximize the perceived performance and consistency of high-value actives—without altering the formulation itself.

For brand owners, the value of modern Gua Sha lies not in teaching a ritual, but in offering a repeatable, protocol-based application method. By integrating mechanical skin activation into professional or at-home regimens, brands can elevate products into treatment-driven solutions, enhance user experience, and reinforce a science-informed approach to skincare performance.

The Industry Blind Spot: Why "Educating" the User Isn't Enough

When a consumer uses your premium serum with a Gua Sha tool and experiences skin dragging or breakouts, they don't blame their technique—they blame your product. The problem isn't the consumer's lack of knowledge; it’s the brand's lack of a "Total Delivery Solution." In the high-end market, professional results require a specific physical environment that standard serums, oils, and lotions simply cannot provide. To achieve professional-grade results, a dedicated Gua Sha medium must meet three critical physical requirements—criteria that most all-purpose skincare products are not designed to fulfill:

1. Low Friction with Controlled Glide

Ensures smooth, consistent movement across the skin surface, helping minimize mechanical stress, micro-irritation, and friction-related discomfort during repetitive strokes.

2. Extended Working Time

Maintains stable slip without premature absorption or drying, allowing a controlled and uninterrupted 5–10 minute protocol for optimal skin activation.

3. Post-Application Compatibility

Designed to absorb efficiently after treatment or integrate seamlessly with subsequent skincare steps, without leaving a heavy or occlusive residue that interferes with active delivery.

The Strategic Solution: BIOCROWN’s "Protocol-Based" R&D

When paired with Biocrown’s high-performance formulations (such as CICA for soothing or Exosomes for repair), Gua Sha acts as a physical engine: Fascia Release, Temperature Modulation, Visual Marketing. We don't just provide a bottle; we provide a "Skin Activation Protocol", turning a simple tool-based massage into a deep-tissue recovery session.