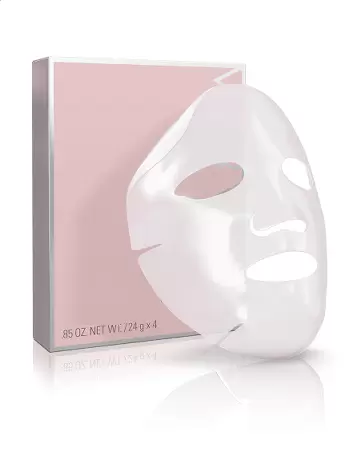

Private Label Facial Mask Bio Cellulose Sheet Mask Manufacturing

XEA0103

Bio Cellulose Mask Manufacturer in OEM / ODM, customized Formulas and White Label service

Elevate Your Brand: Biocrown's Bio-Cellulose Solution for Premium Market

Biocrown's Bio-Cellulose Masks are designed for cosmetic brands, dermatology clinics, and skincare manufacturers. We offer OEM/ODM, customized formulas, enabling you to create unique Bio Cellulose masks that cater to your brand's specific needs; and help you stand out in the competitive skincare market.

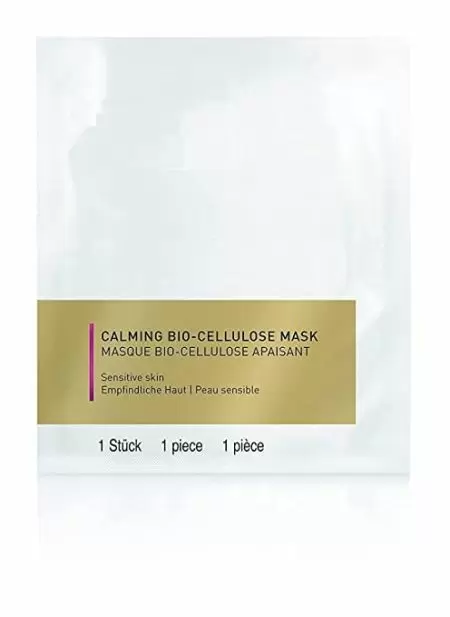

BIOCROWN's Bio-Cellulose Sheet Mask - Made of 100% Cellulose for Maximum Absorption

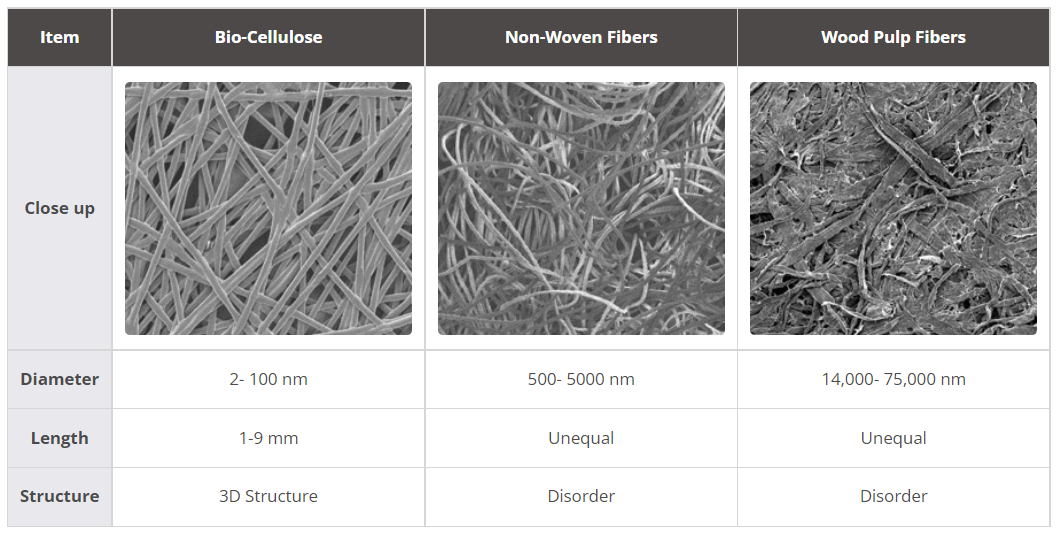

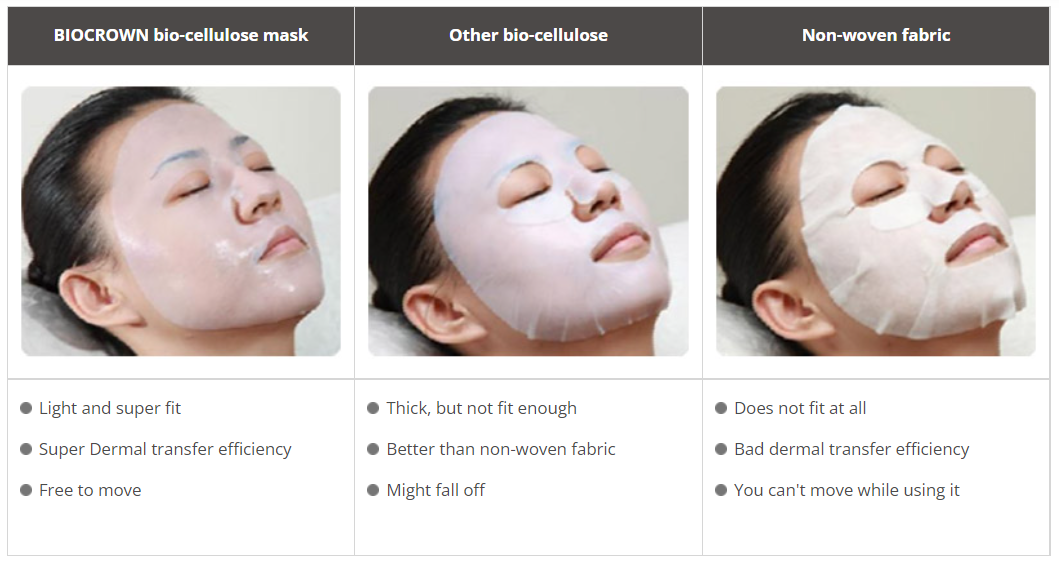

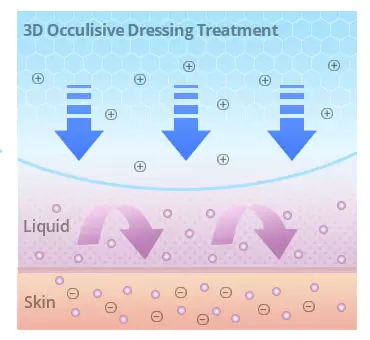

As a leading Bio Cellulose Mask Manufacturer, BIOCROWN is committed to producing top-notch skincare products that harness the natural benefits of the Bio cellulose material. It is soft, moisturizing, and enables the skin to breathe. Bio-cellulose is produced through microbial fermentation, creating a unique 3D network that perfectly conforms to facial contours. This forms a “micro-pressure delivery system”, ensuring the serum stays locked in and is gently “pressed” into the skin rather than evaporating. It is composed of 100% cellulose and is 100% biocompatible, natural fibers that cause no irritation to the skin and are totally environmentally friendly.

BIOCROWN's Innovative Bio-Cellulose Sheet Mask - 72% Moisture Retaining On Skin

How bio-cellulose mask works on your skin

To nourish your skin with 100% effect, BIOCROWN has developed bio-cellulose sheet mask based on seasoned facial mask manufacturing experience. The bio-cellulose sheet mask is designed to deliver nutrition to the deep layers of the skin that is empowered with its natural fiber material. Bio-cellulose sheet mask is made of fermented bacteria and is commonly used in the medical industry. It's 100% compostable (Eco-friendly) and attaches to every part of your face. The imprints of pores and wrinkles on the sheet prove its superior adhesion. BIOCROWN's Natural Bio Cellulose Mask is perfect for transferring and delivering moisture to the skin. Lab tests show that after using bio-cellulose sheet mask, the moisture retained on the skin is 72% higher than in other fabrics.

BIOCROWN - Bio-Cellulose Sheet Mask Bulk Supplier With 10,000 Formulations

With over ten years of facial mask manufacturing experience and over 10,000 mask formulations, our bio-engineered cellulose sheet mask is made to attach to every part of your skin with anti-aging and whitening focuses.

Elevate Your Private Label with BIOCROWN’s Customized Bio-Cellulose Mask Solutions

Experience the revolutionary power of BIOCROWN’s ODM Bio-Cellulose Mask; expertly developed to deliver optimal skincare results for a fresh, rejuvenated, and radiant complexion. As a professional OEM/ODM manufacturer, BIOCROWN specializes in customizing bio-cellulose mask formulas to match your brand’s unique vision and market positioning. Our advanced R&D capabilities allow us to design masks infused with high-performance, multi-functional ingredients that target specific skincare needs. We offer a wide range of customizable active ingredients, including hydrating, brightening, anti-acne, anti-aging, soothing, etc. With BIOCROWN’s expertise in bio-cellulose mask manufacturing, we help your brand create skincare products that combine scientific innovation with natural effectiveness, ensuring outstanding performance and market appeal.

BIOCROWN's bio-cellulose facial mask can be formulated by adding various ingredients.

Facial sheet fabrics include gold, silver foil mask, wood pulp fiber sheet, cotton, charcoal, clay and hydrogel. Whether it's for sensitive skin, oily skin, acne-prone skin and mature skin or combination skin, the key is to allow the concentrated serum to completely penetrate into your skin, through soaked sheets. A facial treatment facial mask intensively infuses liquid-based formulas into your skin through a sheet mask to pamper the skin. The sheet mask acts as a carrier to ensure the serum goes in deep and fast into your skin without evaporating into the air. Most sheet masks last 15-20 minutes before drying out. Although a facial sheet covers the whole face, there are sections missed out because of the uneven surface.

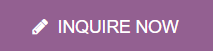

Multi Bio-Cellulose Patches for Targeted Skincare Solutions

As a professional OEM/ODM facial mask manufacturer, BIOCROWN offers a wide selection of bio-cellulose mask sheets designed for different areas.

Thanks to its exceptional fit, bio-cellulose is ideal for developing premium treatments such as:

- Post-procedure recovery patches

- V-line lifting & firming masks

- Targeted anti-aging patches for eyes, neck, or other delicate areas

Elevate your brand with a high-value, science-backed flagship mask that delivers real performance and premium positioning.

How to Use

1.Set the mask in place over face, adjusting to the position of the eyes and lips.

2.Gently press over the mask to fit the face.

3.Relax for 40-60 minutes and remove the mask.

4.Gently massage the remaining essence on the face until it is absorbed.

Q&A

1. How long will it take to produce the samples? How many can I get?

-Discussion Fee $80up per item.

-Typically, it will take about 10~14 days for our R&D specialists to develop the formulation and the samples.

-We will provide 5~10 pi+N3:V3eces of samples for testing.

Customized Service

- Exclusive Formulation Bases: Advanced private-label bases for post-procedure recovery, lifting & firming, and brightening, ready for premium positioning.

- Upgraded Packaging Proposals: Design recommendations tailored for high-end products.

- Tiered Pricing: Transparent product unit cost and regulatory testing fees.

- MOQ: 5000 pcs/SKU/batch.

- Contact our consultants today to reserve your production schedule for your 2026 flagship mask.

Our Advantage

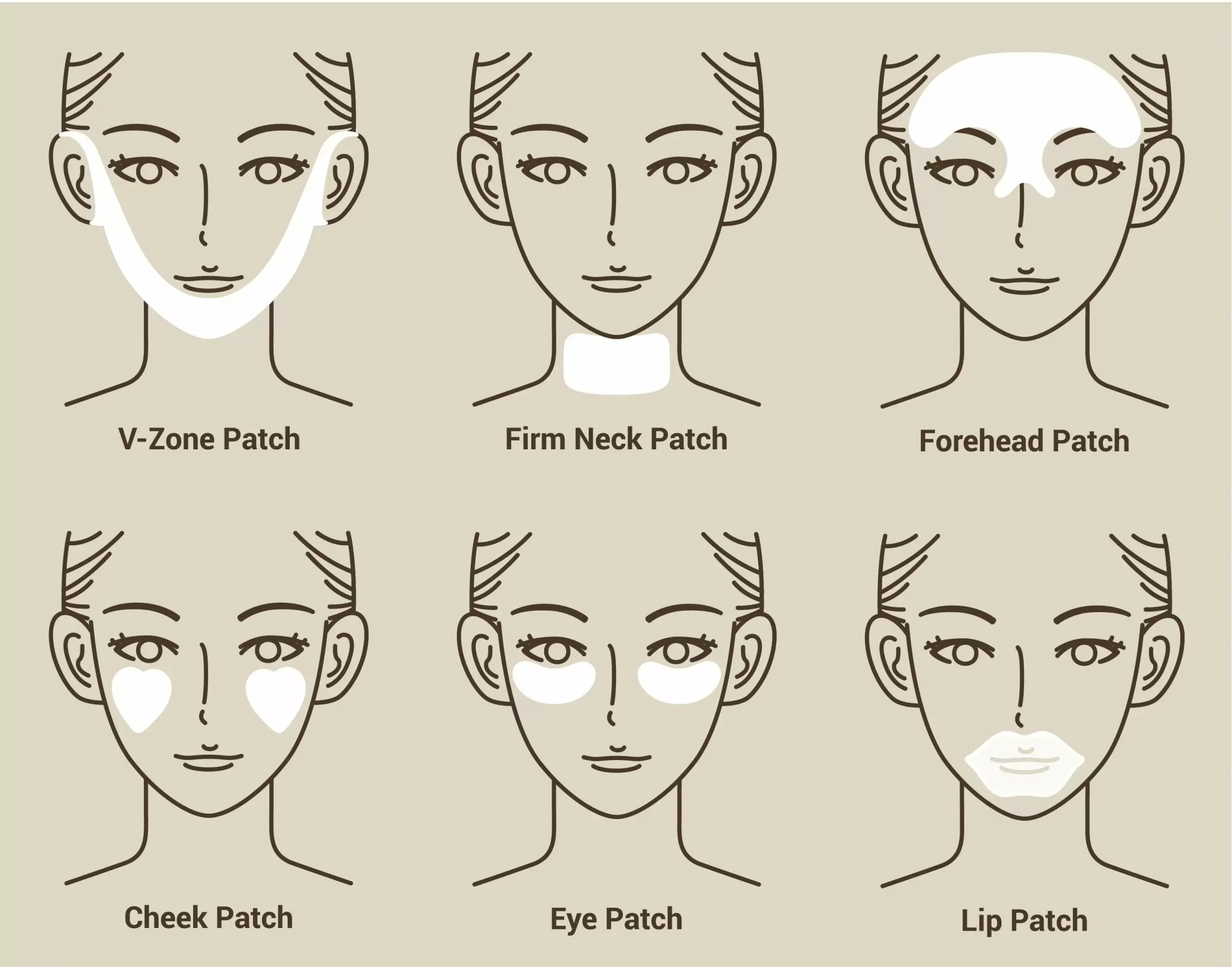

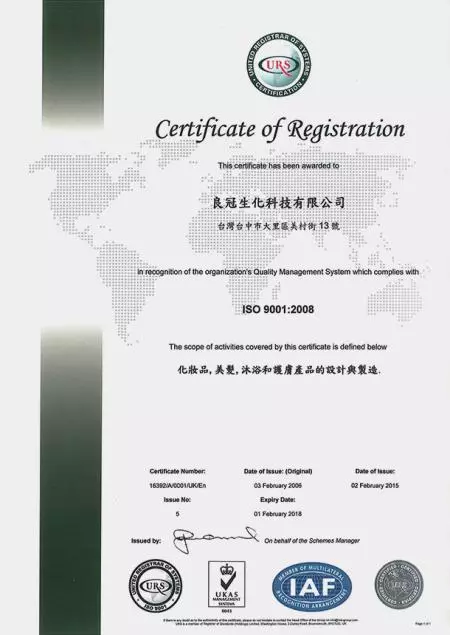

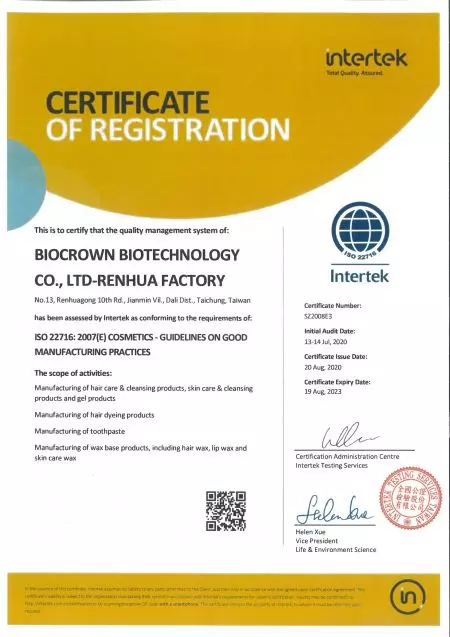

- Certification: GMP, MSDS, SGS, ISO 9001:2008; ISO 22716:2007; ISO 14001

- Our biocellulose has been recognized in Europe, successfully receiving its PIF (Product Information File) in 2018.

- Provide professional OEM, OBM, ODM service around the world with the best price, good quality and large quantities.

- Strict quality and safety control- Packaging material QC, Raw material QC, Purified Water QC, Semi-finished products QC, Finished products QC, Packaging QC.

Certificates

-

Certificate of ISO9001-2008

-

Certificate of ISO22716

-

Certificate of Ecocert Greenlife COSMOS

- Photo

-

-

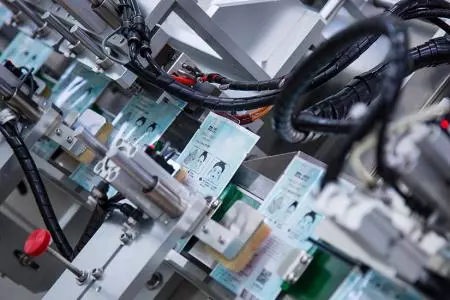

Process procedure of bio-cellulose sheet mask production - bacteriacultivation

-

噴印機台

-

Process procedure of bio-cellulose sheet mask production - 面膜自動填充

-

Process procedure of bio-cellulose sheet mask production - 裝盒

-

Process procedure of bio-cellulose sheet mask production - 標簽黏貼

-

Process procedure of bio-cellulose sheet mask production - L型收縮機 POF 封模收縮

-

Process procedure of bio-cellulose sheet mask production - L型收縮機 POF 封模收縮

-

Process procedure of bio-cellulose sheet mask production - L型收縮機 POF 封模收縮

-

- Movies

-

BIOCROWN Bio-Cellulose Sheet Masks Leakage Test

Facial Mask | Bio-Cellulose Sheet Mask Ingredient Automatic Filling Equipment

Facial Mask | Bio-Cellulose Sheet Mask Automatic Packaging Equipment

- FAQ

- Download

-

Private Label Facial Mask Bio Cellulose Sheet Mask Manufacturing | Biocrown’s Advanced Manufacturing: Cleanroom, RO Systems & Quality Control

With over 48 years of experience, Biocrown Biotechnology Co., Ltd. has established itself as a leading manufacturer in the skincare and beauty industry. Founded in Taiwan in 1977, Biocrown produces a diverse range of high-quality products, including serums, face masks, body scrubs, collagen creams, and intimate care solutions. All Private Label Facial Mask Bio Cellulose Sheet Mask Manufacturing products are developed to meet stringent international standards such as ISO 22716:2008, ISO 14001:2015, GMP, and COSMOS/ECOCERT certifications, ensuring reliability and performance for customers worldwide.

BIOCROWN’s commitment to quality is evident through its advanced processes, including formulation design, cleanroom production, and the use of an RO water purification system. From filling and sealing to packaging design, every stage adheres to global certifications like HALAL, EU PIF, and US Federal 209D standards. By combining decades of expertise with cutting-edge technology, Biocrown continues to provide dependable multi-beauty solutions for businesses seeking premium skincare manufacturing services.

For over 48 years, BIOCROWN has been a leading provider of high-quality skincare, body care, and face care products. Utilizing advanced technology and industry expertise, BIOCROWN delivers customized solutions designed to meet the unique needs of every customer, ensuring exceptional results and satisfaction.