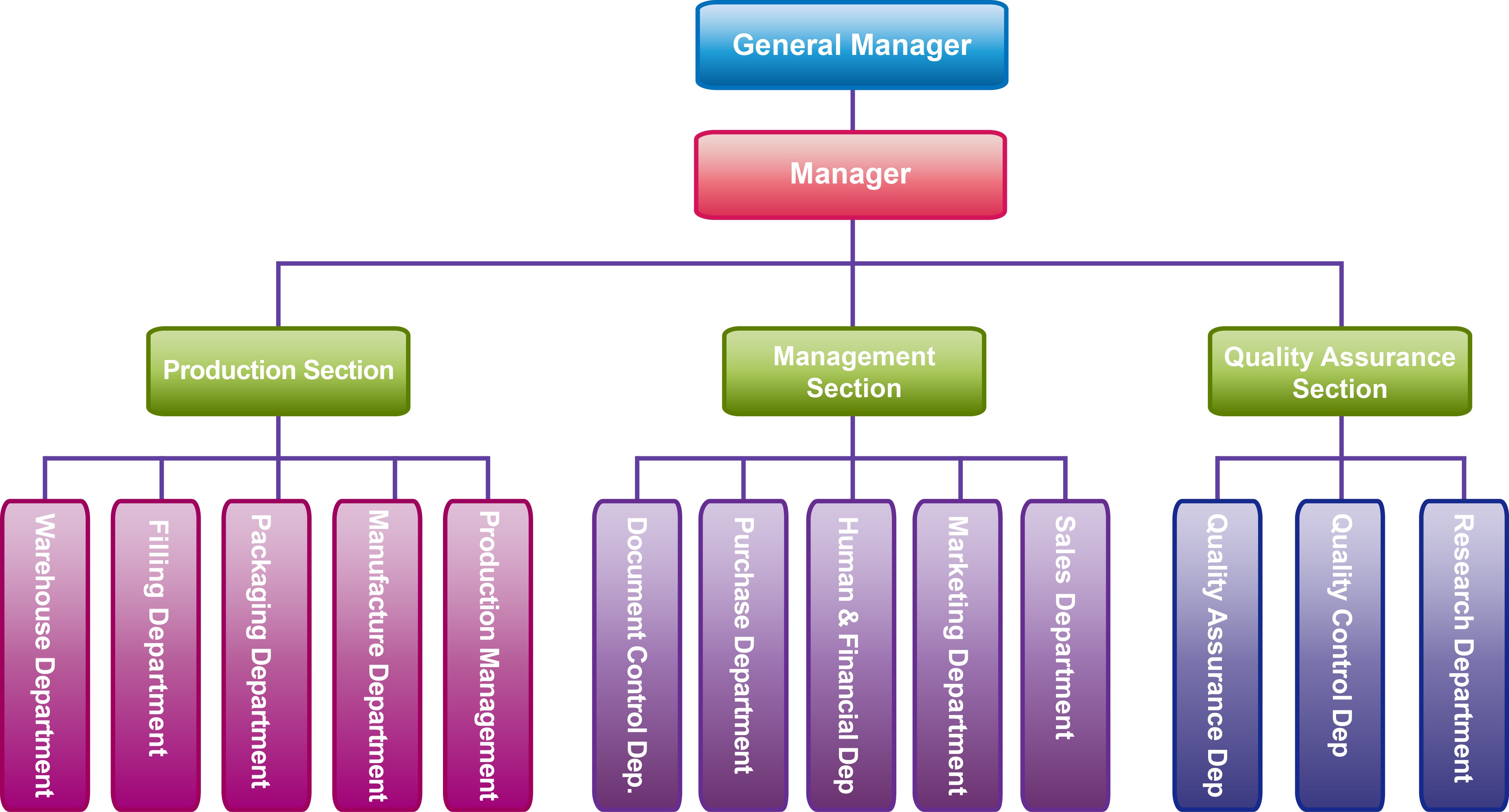

Management & Organization

Biocrown aims to provide the full OEM/ODM turnkey service including formula development, manufacturing, packaging and label-making.

Biocrown provides comprehensive private-label skincare solutions for our clients. To meet customers' demands and expectations while delivering quality service, our team ensures that all operations strictly follow GMP regulations and continuously improve management practices.

Management Section

Contact window for each department of factories.

Main coordinating and communicating bridge for each departments.

Supervise production process.

Manage administrative work of factories.

Manage customized orders.

Assist in education and training course of new ’ manufacturing processes.

Supervise the operation of ISO and GMP.

Review and check customers’ orders and contracts.

Supervise and assist a client’s complaint.

Features and Advantages

Integrate each section’s information to establish cross-sectorial communication mechanism.

Utilize each section’s resources to create new and effective resource using methods.

In the most cost-effective method to manufacture orders.

Sales Department

Collect business and market information to report market forecasts.

Make business promotion planning and check cooperating vendors’ validation customers development and visit.

Assist to handling clients' question.

Coordinate clients' samples and orders' follow-up manufacturing process.

Handle a client'\’s complaint.

Features and Advantages

Customers' specific consultant to accurate understand and communicate a customer's need.

Respond customer question in time.

Confirm a customer's goals and track its operating status.

Human & Financial Department

Coordinate general affairs of company personnel.

Operate recruitment of company personnel.

Organize company’s personnel training planning.

Execute company administration and personnel.

Features and Advantages

Recruit the best people for the company.

Arrange job knowledge training course to upgrade company staff’s professional knowledge and work effectively.

Purchasing Department

Execute company’s procurement.

Purchase raw and packaging materials.

Purchase equipment and office supplies and tack domestic procurement.

Evaluation co-operating vendors.

Features and Advantages

Search the best raw and packaging materials for clients.

Quality Assurance Section

Follow ISO and GMP’s regulations to develop, implement and maintain them

Supervise and manage laboratories’ operation

Review raw materials and package materials’ qualities

Review semi-finished ‘ qualities

Review finished ’ qualities

Train and communicate for ISO and GMP systems

Assist the assessment for suppliers of raw materials and packaging materials

Review a release of finished product

Features and Advantages

Strictly control raw materials and finished qualities.

R&D Department

According to market trends and sales’ need to develop new

Assist sales to provide new ’ training course and information

Collect new raw materials’ information

Modify and manage new developed formulation

Build up, modify and select manufacturing equipment

Manage developed formulation

Make stability test for a new formulation’s using container

Provide base test for new formulation

Management of production formulation

Features and Advantages

Get the market’s instant information

Research and develop new formulation to meet the future market trends

Provide a stability and safe product for a client

Quality Control Department

Inspect for pre-shipment

Inspect for raw materials

Inspect and control for semi-finished

Inspect, manage and track for finished

Maintain and clean for all of inspecting equipment

Inspect and culture for microbial

Manage finished ’ samples

Features and Advantages

Control a product’s quality strictly for each client

Ensure production equipment clean

Track and file for samples and mass productions’ qualities

Quality Assurance Department

Manage documents of inspected and released raw materials

Ensure all inspect equipment clean

Manage storage of semi-production and developed samples

Analyses and tracking modified manufacturing process

Assist package materials’ inspection and release

Features and Advantages

Ensure semi-finished raw materials and finished product quality

Effective modify the production process to achieve the most effective and safe manufacturing process

Production Section

Arrange customers orders’ production schedule

Implement Standard Operation Process to arrange production schedule

Review and inventory raw and package materials’ storage

Monitor and ensure production machinery and container clean

Monitor and maintain clean room and raw material room’s clean

Monitor and maintain pure water facility’s operation and clean

Implement packaging, filling, manufacturing personnel’s education and training

Features and Advantages

100K clear room standing and following US Federal 209D specifications to ensure manufacturing environmental quality

Strictly following GMP and ISO-22716 regulation to effective arrange manufacturing schedule

Well organization of manufacturing department to ensure package, filling, manufacturing and warehouse teams operation effective

Production Management Department

Implement orders’ production schedule

Assist to manage raw and package materials

Coordinate to deposit raw and packing material into the factories

Execute manufacturing and packing production schedule

Features and Advantages

Effectively coordinating and executing raw and packing materials’ purchase

Effectively assist in the management of manufacturing raw and packing materials

Effectively arrange orders’ production schedule

Warehouse Department

Manage and file customized package materials

Ensure warehouse environmental clean and storages’ well organized

Assist shipment

Provide monthly warehouse inventory report to the relevant departments

Features and Advantages

Accurately monitor warehouse’s storage quantities

Effectively manage warehouse’s storage

With automatics storage system, effectively control production materials’ quality and safe stock quantities

Management